Got the winter blues? Or, are you trying to think of a good project to occupy your time this winter? How about rigging your mainsail with a single-line reefing system. If you sail alone much of the time like I do, a single-line reefing system is great. Snickerdoodle has two full reefs for the mainsail; and both are rigged with a single-line system. This means that I can easily tuck in a reef in about thirty seconds - - AND never have to leave the cockpit.

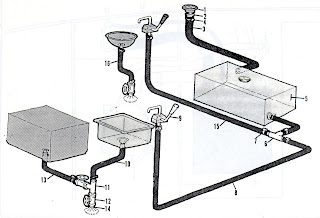

| These two pictures are of Garry Hoyt's single-line reefing system. Secure a stainless steel eye-strap to the port side of the boom near the clew of the mainsail. Then secure three cheek blocks on the starboard side of the boom. One near the clew corner; one four or five inches aft of the gooseneck; and the third near the gooseneck. Install a turning block near the mast base and a line organizer if you need one. And finally install a cleat near the aft end of the cabin top. The line is secured to the eye-strap and then rove through the leach reefing point, around the aft cheek block, forward to the next cheek block, up to an reefing hook that is hung in the luff reef point; down through the most forward cheek block and around the turning block, and then back to the cleat on the cabin top. On Snickerdoodle, the line is quarter inch and all of the hardware is appropriately sized. (Of course, make sure that you install the three cheek blocks so that the line runs fairly) |

I originally copied the Garry Hoyt system and it worked pretty well. The only thing that I did not like was the reefing hook. There was additional friction unless I secured a small block to the hook. But the block made the system jam at the forward cheek block. So I designed a modification that has worked well for me for many years now.

The two main changes was to eliminate the middle cheek block; and to install a swivel block at the mast base. Now the reefing line is secured to the eye-strap (I like a "figure-8" knot), then is rove up through the leach reef point, down and around the aft cheek block, forward to the front cheek block, through the luff reef point, and finally down through the swivel block. I use this same sort of system for both the first and second reefing lines. It is easy now to tuck in a reef all by myself - - and then shake it out again when the wind dies down. I generally raise up the aft end of the boom six inches or so with the topping lift before reefing. Then, I simply slack off the main halyard as I pull in on the reefing line. Lower the boom when the reef is tucked in. It works like a charm.

Enjoy your winter project. It's only about a dozen weeks till sailing season commences.

Barnacle Bill Holcomb

BarnacleBillHolcomb@gmail.com